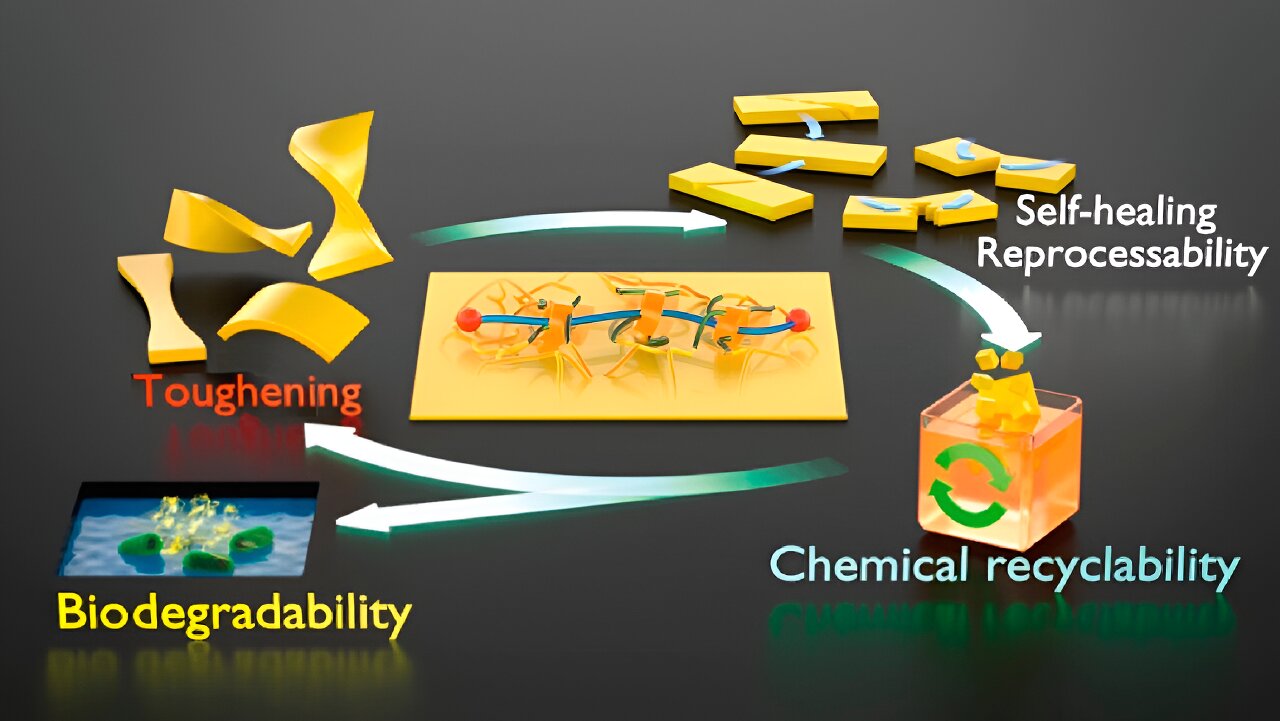

Vitrimers are an innovative class of materials that have sparked interest due to their unique properties, especially in applications related to soft tissues. They combine the durability and strength found in traditional thermosets with the reprocessability and recyclability of thermoplastics due to their ability to undergo bond rearrangement. This makes vitrimers particularly suitable for medical applications, including soft tissue repair, where materials must be adaptable, durable, and capable of integrating with biological tissues.

In soft tissue applications, vitrimers could offer several advantages:

- Biocompatibility and Repairability: Vitrimers can be designed to be biocompatible, making them suitable for integration into biological systems. Their inherent repairability could also be advantageous in soft tissue engineering, where the material could adapt or heal in response to changes in the biological environment.

- Mechanical Properties and Adaptability: The unique viscoelastic properties of vitrimers allow them to mimic the mechanical behavior of natural soft tissues. This adaptability could be crucial in developing more natural-feeling prosthetics or supportive structures that can withstand the dynamic environment of the human body.

- Reprocessability and Sustainability: Vitrimers’ reprocessing ability could lead to more sustainable medical materials, as they can be reshaped or recycled, reducing waste in medical applications.

Vitrimers like silicon elastomer vitrimer composites have been investigated for their thermal conductivity and mechanical properties, finding potential use in thermal interfaces for electronic devices due to their enhanced functional properties. The research also notes that while adding certain components like functionalized boron nitride nanosheets (fBNNS) can affect the healing efficiency, it does not detract from the material’s thermal conductivity, even after multiple healing cycles.

Moreover, the industry has started recognizing the potential of vitrimers. Start-ups like ATSP Innovations and Mallinda are exploring the commercial applications of vitrimers in various fields, including aerospace and automotive sectors, due to their high modulus, high working temperature, and non-flammability. These companies are leveraging the unique properties of vitrimers to create materials for demanding applications.

EU-funded projects like AIRPOXY and ECOXY are driving forward the development of vitrimer composites, aiming to create materials that are reprocessable, repairable, and recyclable (3R). These projects are particularly focused on reducing manufacturing costs and times, and enhancing the sustainability of materials used in sectors such as aerospace and construction.