Polyrotaxane vitrimers are a relatively new class of plastics that have been gaining interest in science and industry for their ability to enhance the toughness of materials and make them more environmentally friendly. Here’s what you need to know about polyrotaxane vitrimers:

What are Polyrotaxane Vitrimers?

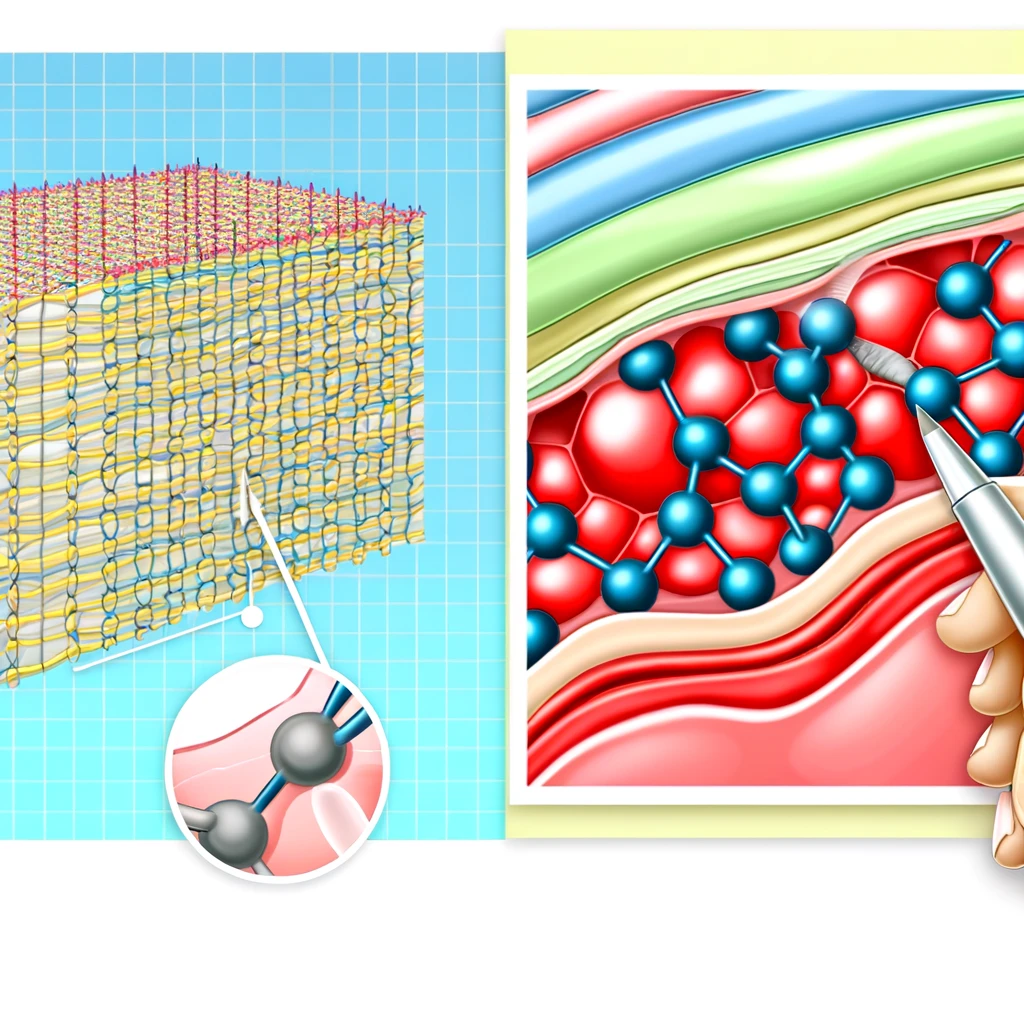

Polyrotaxane vitrimers are a type of plastic that combines the properties of vitrimers and polyrotaxanes. Vitrimers are solid and strong at lower temperatures, like thermoset plastics, but can be reformed into different shapes at higher temperatures. Polyrotaxanes are molecules that consist of a linear polymer chain threaded through a series of cyclic molecules called “stoppers.” By adding polyrotaxanes to vitrimers, researchers have been able to create materials that are stronger, more stretchy, and more self-healing than traditional vitrimers ( 1 ).

How are Polyrotaxane Vitrimers Made?

Polyrotaxane vitrimers are made by adding polyrotaxanes to vitrimers. Researchers at the University of Tokyo have developed a new type of polyrotaxane vitrimer called VPR by adding polyrotaxanes to an epoxy resin vitrimer. VPR can hold its form and has strong internal chemical bonds at low temperatures. However, at temperatures above 150 degrees Celsius, those bonds recombine and the material can be reformed into different shapes. VPR is over five times as resistant to breaking as a typical epoxy resin vitrimer, repairs itself 15 times as fast, can recover its original memorized shape twice as fast, and can be chemically recycled 10 times as fast as the typical vitrimer. It even biodegrades safely in a marine environment, which is new for this material.

What are the Applications of Polyrotaxane Vitrimers?

Polyrotaxane vitrimers have wide-reaching applications for a more circular economy to recirculate resources and reduce waste, from engineering and manufacturing to medicine and sustainable fashion. They can be used to create stronger and more durable materials that are also more environmentally friendly. For example, VPR can be chemically recycled 10 times as fast as the typical vitrimer, making it a more sustainable option for manufacturing. It can also biodegrade safely in a marine environment, which is important for reducing plastic waste in the ocean.

Polyrotaxane vitrimers have wide-reaching applications for a more circular economy to recirculate resources and reduce waste, from engineering and manufacturing to medicine and sustainable fashion. They can be used to create stronger and more durable materials that are also more environmentally friendly. For example, VPR can be chemically recycled 10 times as fast as the typical vitrimer, making it a more sustainable option for manufacturing. It can also biodegrade safely in a marine environment, which is important for reducing plastic waste in the ocean.

Polyrotaxane vitrimers have been gaining interest in science and industry for their unique properties and potential applications. Here are some of the latest research trends and emerging applications of polyrotaxane vitrimers:

Environmentally friendly and sustainable materials: Polyrotaxane vitrimers have self-healing properties, shape memory, and are chemically recyclable and marine biodegradable. They are attracting attention in applications such as adhesives and carbon fiber composite materials.

Additive manufacturing: Polyrotaxane vitrimers can be used in material extrusion additive manufacturing to create 3D-printed objects. High-density polyethylene (HDPE) and HDPE vitrimers (HDPE-V) were successfully processed using a screw-assisted 3D printer.

Medicine: Polyurethane vitrimers have been developed for use in medicine due to their unique properties, including shape memory and self-healability. They have potential applications in drug delivery and tissue engineering.

Engineering and manufacturing: Polyrotaxane vitrimers can be used to create stronger and more durable materials that are also more environmentally friendly. They can be chemically recycled and biodegrade safely in a marine environment, making them a more sustainable option for manufacturing.

Sustainable fashion: Polyrotaxane vitrimers can be used to create more sustainable and environmentally friendly fashion. They can be used to create stronger and more durable fabrics that are also biodegradable.

In conclusion, polyrotaxane vitrimers are a promising new class of plastics that combine the properties of vitrimers and polyrotaxanes to create stronger, more durable, and more environmentally friendly materials. They have wide-reaching applications in engineering, manufacturing, medicine, and sustainable fashion, and could help to reduce plastic waste and create a more circular economy. Ongoing research and development in this field will likely lead to even more innovative applications and uses for polyrotaxane vitrimers in the future.