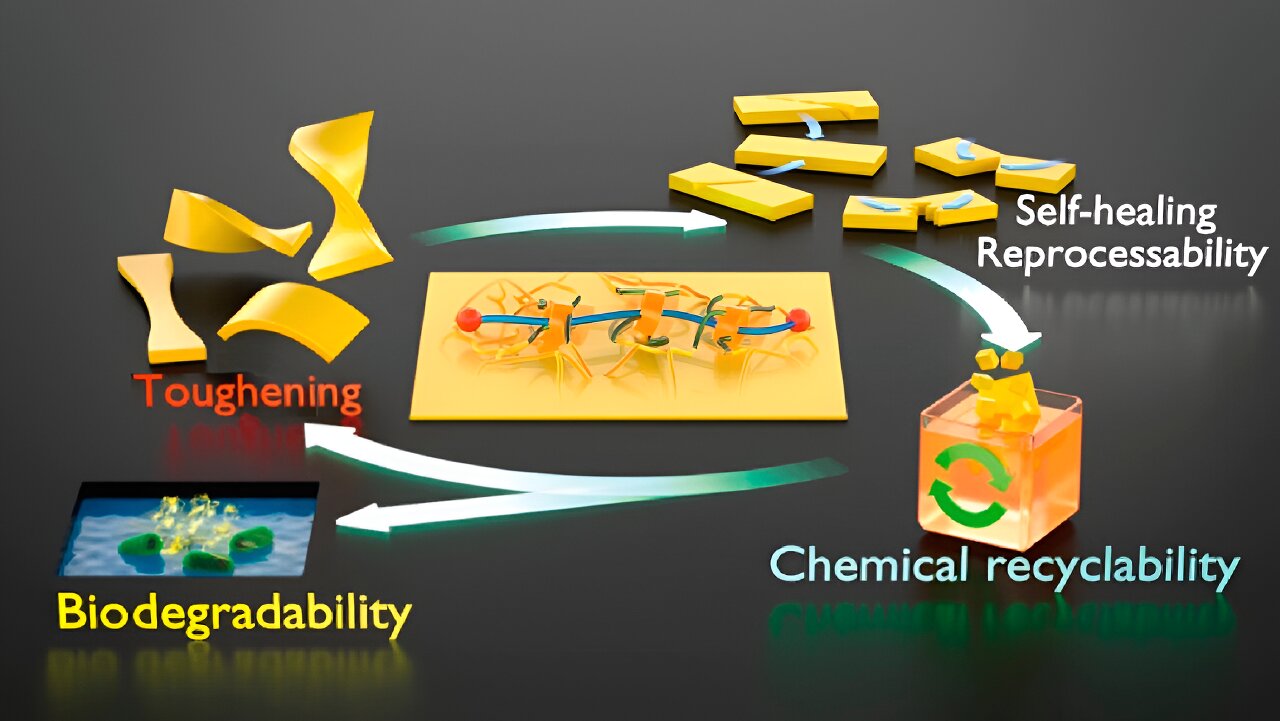

The advent of vitrimer technology is poised to revolutionize a multitude of industries with its smart material capabilities. Vitrimers are not just another addition to the polymer family; they are a groundbreaking development that offers self-healing, reprocessable, and adaptive properties. This article explores the myriad of applications where vitrimers stand out, providing solutions to challenges that traditional materials have been unable to address.

Medical Marvels: Vitrimers in Healthcare

Self-Healing Surgical Implants

The medical industry is on the brink of a new era with vitrimer technology. Self-healing surgical implants represent a significant leap forward. These smart materials can autonomously repair minor damages within the body, potentially eliminating the need for additional surgeries—a common occurrence with traditional implants. This not only improves patient outcomes but also reduces the healthcare system’s burden.

Adaptable Wound Dressings

Vitrimers are set to transform wound care with dressings that dynamically adapt as wounds heal. These advanced materials can modify their properties to maintain the ideal moisture and air permeability, which are crucial for different healing stages. This adaptability ensures optimal healing conditions, potentially reducing healing times and minimizing scar formation.

Dynamic Tissue Scaffolds

In tissue engineering, vitrimers are paving the way for dynamic scaffolds that evolve during the tissue regeneration process. These scaffolds can adjust their mechanical properties in response to the maturing tissue, providing a supportive structure that degrades at a controlled rate. This capability ensures that the scaffold supports the tissue as it grows, eventually leaving behind a healed tissue without any foreign material.

Construction Innovation: Vitrimers Building the Future

Self-Repairing Concrete

Vitrimers are set to redefine the construction industry with self-repairing concrete. This smart material can autonomously heal cracks, which are a common and costly problem in construction. By extending the life of structures and reducing the need for maintenance, vitrimers could save millions in infrastructure costs and significantly reduce the carbon footprint associated with concrete production and repair.

Adaptive Insulation Materials

Energy efficiency in buildings is a growing concern, and vitrimers offer an innovative solution with adaptive insulation materials. These materials can change their thermal conductivity in response to temperature changes, ensuring optimal insulation performance year-round. This responsiveness could lead to a reduction in energy consumption, making buildings more sustainable.

Reconfigurable Piping Systems

Vitrimers could revolutionize plumbing with reconfigurable piping systems. These systems can be reshaped to repair or reconfigure without the need for extensive reconstruction, offering a sustainable and cost-effective alternative to traditional piping. This capability is particularly beneficial in areas prone to frequent layout changes or expansions.

Textile Transformation: Vitrimers in Fabric Innovation

Self-Healing Fabrics

The textile industry is on the cusp of a sustainable revolution with vitrimer-based self-healing fabrics. These materials can repair tears or punctures, significantly extending the life of garments. This innovation not only reduces waste but also caters to the growing consumer demand for durable and sustainable clothing options.

Thermo-Adaptable Clothing

Vitrimers are weaving their way into the fabric of the future with thermo-adaptable clothing. These smart textiles can adjust their insulation properties in response to body temperature or external conditions, providing unparalleled comfort and performance. This technology could lead to a new class of clothing that adapts to the wearer’s needs, potentially reducing the need for multiple layers or frequent changes.

Energy Solutions: Vitrimers in Storage and Conversion

Self-Healing Battery Electrodes

In the realm of energy storage, vitrimers are charging ahead with self-healing battery electrodes. These electrodes can repair themselves, prolonging battery life and enhancing performance. This is particularly crucial as the demand for reliable and long-lasting batteries grows with the rise of electric vehicles and renewable energy systems.

Adaptive Solar Panel Coatings

Vitrimers are shining a light on the future of solar energy with adaptive solar panel coatings. These coatings can self-heal from environmental damage, maintaining efficiency and extending the lifespan of solar panels. This self-healing capability is essential for maximizing the return on investment in solar energy infrastructure.

In conclusion, vitrimers are not just a scientific curiosity; they are a versatile and practical solution to some of the most pressing challenges across various industries. From healthcare to construction, and energy to textiles, vitrimers offer properties that traditional materials cannot match. As research and development in this field continue to advance, we can expect vitrimers to become a cornerstone of sustainable and innovative material science.

Electronics Evolution: Vitrimers in the Tech World

Self-Repairing Circuit Boards

The electronics industry could see a significant reduction in waste with the introduction of vitrimer-based self-repairing circuit boards. These innovative materials can autonomously mend breaks or faults, potentially extending the lifespan of electronic devices and reducing the environmental impact of e-waste. This self-healing ability is not only eco-friendly but also cost-effective, as it could decrease the need for repairs and replacements.

Reprocessable Electronic Components

Vitrimers are poised to transform the electronics market with reprocessable components. In a world where electronic waste is a growing concern, the ability to depolymerize and reform components into new electronics is a game-changer. This circular approach to manufacturing could lead to a more sustainable electronics industry, where materials are reused rather than discarded.

Adhesive Advancements: Vitrimers’ Sticky Solutions

Reversible Adhesives

The unique reversible bonding capabilities of vitrimers have opened the door to innovative adhesive applications. These smart adhesives can be debonded and rebonded without losing their stickiness, which is ideal for applications requiring temporary bonding or modularity. This feature is particularly useful in industries such as construction, where it can facilitate the easy assembly and disassembly of components.

Coating Breakthroughs: Vitrimers for Surface Protection

Self-Healing Protective Coatings

Vitrimers are making a splash in the coatings industry with their self-healing properties. These advanced materials can autonomously repair scratches or damages, preserving the material underneath. This technology is particularly beneficial for high-wear surfaces, where longevity and appearance are critical.

Environmentally Responsive Coatings

The ability of vitrimers to change their properties in response to environmental triggers has led to the development of environmentally responsive coatings. These coatings can adapt their behavior, such as becoming more hydrophobic in the rain, providing dynamic protection for a variety of surfaces.

Packaging Paradigm Shift: Vitrimers in Sustainable Solutions

Reformable Packaging Solutions

In the packaging industry, vitrimers offer a sustainable solution with their ability to be reshaped for multiple uses. This property allows for the design of packaging that can be easily recycled or repurposed, reducing the environmental impact of packaging waste and supporting a more sustainable economy.

Automotive Advancements: Vitrimers Driving Innovation

Self-Healing Car Interiors

The automotive sector can benefit from vitrimers in the form of self-healing car interiors. Materials that can repair wear and tear autonomously will maintain the vehicle’s aesthetic and functional integrity over time, enhancing the user experience and vehicle value.

Reconfigurable Car Parts

Vitrimers also enable the production of reconfigurable car parts. This adaptability allows for parts to be reshaped for different models or functionalities, offering a flexible and sustainable approach to automotive manufacturing.

Aerospace Achievements: Vitrimers Taking Flight

Damage-Tolerant Aircraft Components

In aerospace, vitrimers are set to take off with lightweight, damage-tolerant materials. These components can self-heal from micro-damages caused by environmental stressors, which is crucial for safety and efficiency in the aerospace industry.

Vitrimers in Regenerative Medicine

Adaptive Drug Delivery Systems

Vitrimers are making waves in regenerative medicine with adaptive drug delivery systems that can change their release profiles in response to physiological conditions. This precision medicine approach ensures that drugs are delivered where and when they are needed most.

Self-Healing Biocompatible Implants

Biocompatible implants made from vitrimers that can recover from minor damages could significantly reduce the risk of implant failure and the need for revision surgeries.

3D Printing Progress: Vitrimers Reshaping Manufacturing

Recyclable 3D Printing Filaments

The 3D printing industry is embracing vitrimers with recyclable filaments that can be depolymerized and reprinted, fostering a more sustainable approach to manufacturing.

Vitrimers are not just a material; they are a solution. Their unique properties offer unprecedented opportunities to address some of the most challenging issues faced by industries today. As we continue to explore and harness the potential of vitrimers, we move closer to a future where materials are not only functional but also intelligent and sustainable.

Sustainable Manufacturing: Vitrimers Leading Eco-Friendly Production

Closed-Loop Material Cycles

Vitrimers are the key to truly closed-loop material cycles in manufacturing. Their ability to be fully recycled without significant degradation of properties means that products can be created, used, reprocessed, and remade, all without leaving the production cycle. This is a monumental step towards sustainable manufacturing practices, reducing the need for new raw materials and minimizing waste.

Eco-Friendly Production Processes

The production processes involving vitrimers can be designed to be more eco-friendly. Since vitrimers can be reprocessed at lower temperatures and without the release of volatile organic compounds (VOCs), they represent a cleaner, greener alternative to traditional plastics and composites manufacturing.

Biodegradable Materials: Vitrimers for a Greener Planet

Environmentally Friendly and Sustainable Materials

Vitrimers engineered to be biodegradable can break down into harmless substances after their useful life, offering an environmentally friendly solution to the persistent problem of plastic pollution. These materials can be designed to degrade in specific environments, such as compost facilities or even in natural settings, ensuring that they do not contribute to the growing issue of microplastics.

Biodegradable Plastics and Polymers

The development of vitrimer-based biodegradable plastics and polymers could revolutionize packaging, agriculture, and other industries heavily reliant on single-use plastics. These materials promise to maintain the utility of traditional plastics while ensuring that they do not remain in the environment for centuries.

Repairable Materials: Vitrimers in Self-Repairing Technologies

Self-Repairing Materials

The self-repairing capabilities of vitrimers are not limited to large structures or visible damages. On a microscopic scale, these materials can autonomously mend themselves, potentially extending the lifespan of products and reducing the need for maintenance or replacement.

Recyclable and Repairable Composite Materials

Vitrimers also offer a solution to the challenge of recycling composite materials, which are typically difficult to reprocess due to their complex structure. Vitrimers can be designed to disassemble at a molecular level and then be reformed, allowing for the recycling of composite materials without compromising their strength or structural integrity.

Environmental Applications: Vitrimers for a Sustainable Future

Sustainable Materials for Environmental Protection

Vitrimers can be engineered to interact with environmental pollutants, capturing and neutralizing them. This makes them ideal for applications in environmental protection, such as in water treatment or air purification systems.

Recycling and Waste Reduction Solutions

The inherent recyclability of vitrimers presents a significant opportunity for waste reduction. By designing products with vitrimers, manufacturers can ensure that at the end of a product’s life, the material can be efficiently reprocessed and reused, rather than contributing to landfill.

Sports Equipment: Vitrimers Enhancing Athletic Performance

Durable and Adaptive Sports Equipment

Sports equipment made from vitrimers can adapt to the athlete’s performance needs, offering durability and adaptability. For example, a vitrimer-based grip on a tennis racket could adjust its tackiness based on humidity or user preference, enhancing the player’s performance.

Sustainable and High-Performance Sporting Goods

The sports industry is increasingly looking for sustainable options that do not compromise on performance. Vitrimers could provide high-performance sporting goods that are also sustainable, reducing the environmental impact of sports equipment without affecting the athlete’s experience.

Marine Industry: Vitrimers Making Waves

Resilient and Adaptable Marine Materials

The marine industry can benefit from vitrimers in the form of resilient and adaptable materials that withstand harsh oceanic conditions. These materials can self-heal after damage from impacts or abrasive sea water, which is crucial for the longevity of marine vessels and structures.

Eco-Friendly and Durable Marine Components

Vitrimers offer an eco-friendly alternative to traditional marine components. They can be designed to be non-toxic and biodegradable, reducing the environmental impact of marine operations and helping to preserve aquatic ecosystems.

Renewable Energy Sector: Vitrimers Powering Sustainability

Sustainable Materials for Renewable Energy Infrastructure

In the renewable energy sector, vitrimers can be used to create sustainable materials for infrastructure, such as wind turbine blades or solar panel frames. These materials can self-heal from wear and tear, extending the life of renewable energy installations and reducing maintenance costs.

Durable and Long-Lasting Renewable Energy Components

The durability and longevity of vitrimer materials are essential for the cost-effectiveness of renewable energy components. By increasing the lifespan of these components, vitrimers can help to lower the overall cost of renewable energy, making it more competitive with traditional energy sources.

In every application, vitrimers offer a compelling combination of durability, adaptability, and sustainability. As industries worldwide strive to become more eco-conscious and efficient, vitrimers stand out as a material solution that can meet the demands of the present without compromising the needs of the future. The ongoing research and development in vitrimer technology promise to unlock even more applications, further solidifying their role as a cornerstone of innovative and sustainable material science.

In conclusion, vitrimers are set to play a pivotal role in the transition to a more sustainable and efficient global economy. Their unique combination of properties—self-healing, reprocessability, adaptability, and durability—makes them an ideal choice for a wide range of applications. From medical implants to renewable energy, and from environmental remediation to sports equipment, vitrimers offer a versatile and sustainable solution that aligns with the goals of a circular economy and reduced environmental impact. As research continues to unlock new potentials for vitrimers, we can anticipate a future where materials are not only used for their function but also for their ability to contribute to a sustainable world.

References:

Vitrimer composites: current status and future challenges